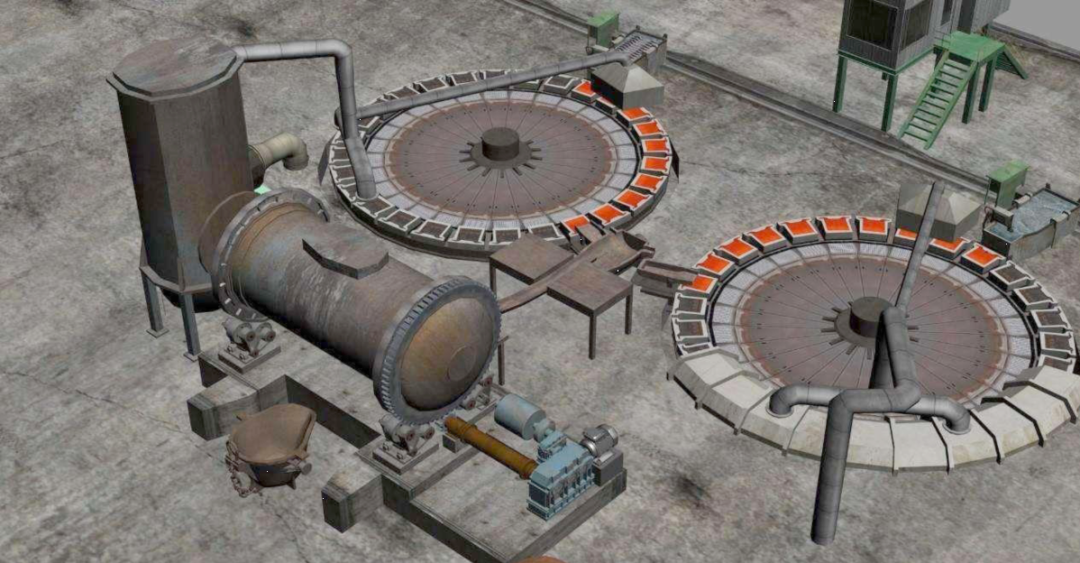

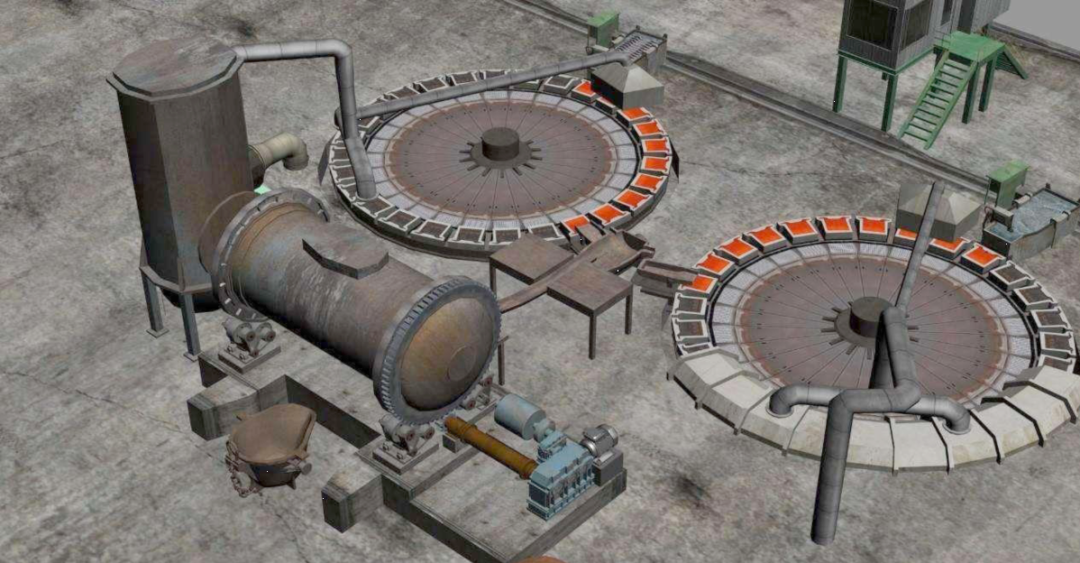

At present, many blister copper refining equipment in my country are anode reverberatory furnaces. The inner brick lining is mainly magnesia-alumina bricks and magnesia bricks. A small amount of sintered magnesia-chrome bricks are used near the slag line of the furnace. The furnace width of the anode reverberatory furnace is small, generally The life of the vault and the furnace top is closely related to the furnace age of the anode reverberatory furnace. The life of the small furnace type, especially the magnesia brick furnace top is generally 3 to 4 months.

The rotary refining furnace is a cylindrical furnace that can be rotated, but it does not have a large number of tuyere in the converter, only two redox holes, and the operation time is short. Due to frequent rotation and no fixed slag line, the erosion of slag and the erosion of molten metal almost occupy more than 2/3 of the inner surface of the furnace. Therefore, the Cr2O3 content of the lined magnesia-chrome brick is generally required to be greater than 22. And the requirements for the copper outlet are higher, and direct-bonded magnesia-chrome bricks or fused magnesia-chrome bricks are often used.