Refractory Coating Materials

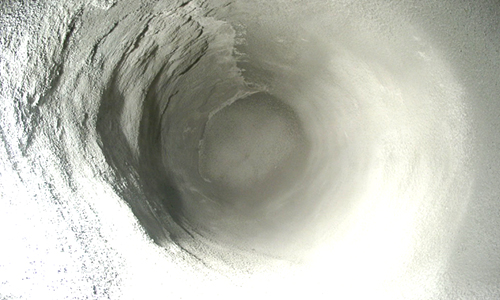

Refractory Coating Material Description

Refractory coating material is also called fire proof dope, fire retardant paint, or refractory wash. It serves as working lining or protection ling of refractory material lining. Refractory coating material has fairly good spreadability, the main application methods of refractory coating material are manual coating and mechanical spraying. By functions of refractory coating materials, they are classified into: cleaning steel coating material, thermal radiation fireproof dope, oxidizing resistant fire retardant paint, heat preservation refractory wash, acid proof coating material and alkali proof coating material, etc. Main raw materials of refractory coating material differ greatly according to their functions.

Cleaning Steel Refractory Coating Material

Cleaning steel coating material is also called tundish coating material. It is alkaline magnesia calcia coating material, used to coat continuous casting tundish working lining. Why this tundish coating material has the function of cleaning steel liquid is because CaO in coating material can adhere oxides(SiO2, Fe2O3, Al2O3, etc), P, S and other impurities in steel liquid.

The main compositions of magnesia calcia tundish coating material are dolomite or calcined magnesia calcia, sintered or fused magnesia. Generally speaking, the higher CaO content, the better the cleaning effect.

Tundish Refractory Coating Material Physiochemical Index

| Item |

TCM-12 |

TCM-32 |

TCM-50 |

| MgO% ≥ |

74 |

54 |

34 |

| CaO % ≥ |

12 |

32 |

50 |

| Bulk Density g/cm3,110℃, 24h |

1.9-2.2 |

1.9-2.2 |

1.9-2.2 |

| Compression strength Mpa(1500℃, 3h) ≥ |

2.5 |

2.5 |

2.5 |

| Linear change rate (1500℃, 3h) % ≤ |

3.0 |

3.0 |

3.0 |

| Application |

Ordinary steel liquid |

Clean steel liquid |

Super clean steel liquid |

Heat Radiation Coating Material

Heat radiation coating material is also called energy saving coating material. It can increase thermal radiation rate of furnace lining surface, so thermal efficiency can be improved. SiC heat radiation coating material is composed of SiC powder, binder and additives. ZrO2-CaO-SiO2 heat radiation coating material has high refractoriness, good structural strength and high temperature corrosion resistance. It can be used as electric heating furnace heat radiation coating layer and gas heating furnace inner lining coating layer.

Oxidizing Resistant Refractory Coating Material

Oxidizing resistant refractory coating material is used to keep carbon refractory(magnesia carbon brick, alumina carbon brick, alumina carbon long nozzle, submerged nozzle and so on) from oxidization. Oxidizing resistant coating material has the following characteristics:

a. Good spreadability, can adhere to carbon refractory products surface firmly.

b. After drying, oxidizing resistant coating material has certain degreed of cohesion strength with carbon products.

Have good film formation ability when coated to lining surface, coating layer won’t crack or spall.

Can form homogeneous dense glaze layer during low temperature and high temperature drying, so oxygen won’t enter inner part and oxidize carbon products.

Acid Proof Refractory Coating Material

Acid proof refractory coating material is made from acid or weak acid powder refractory material (less than 0.088mm), bonders and additives. To prevent crack of the coating material during drying process, short glass fibers or short aluminum silicate refractory fiber are added to the coating material.

Acid proof refractory coating material are mainly used as coating layers of smokestack, flue or acidic material reactor inner lining.

Alkali Proof Refractory Coating Material

Alkali proof refractory coating material are composed of alkali proof refractory powder, bonder and additives, it has good alkaline metal vapor corrosion resistance. Alkali proof coating material or base proof coating material is mainly used in flue, smokestack and industrial atmospheric furnace, where alkali corrosion is strong.

Heat Insulating Coating Material

Heat insulating coating material adopts expansile vermiculite, or expansile perlite, diatomite, lightweight clay clinker, glass fiber, aluminum silicate fiber as main raw material. Silicate cement, aluminate cement, water soluble sodium silicate, or acid aluminum di-hydrogen phosphate can be used as binder. Bentonite and plastic refractory clay can be used as plasticizer.

Heat Insulating Coating Material Index

| Item |

Heat resistant coating material |

Refractory coating material |

| Vermiculite coating material |

Perlite coating material |

Mullite coating material |

Alumina coating material |

| Working temperature |

<700℃ |

<700℃ |

≥1100℃ |

≥1100℃ |

| Bulk density g/cm3 |

0.30-0.50 |

0.30-0.50 |

0.8-1.0 |

1.2-1.6 |

| Thermal conductivity W/(m.k) |

0.06-0.12

350℃ |

0.06-0.12

350℃ |

0.26 |

0.9-1.2

1000℃ |

| Application |

Industrial furnace masonry outer surface |

Industrial furnace masonry outer surface |

High temperature inner lining coating, hot air duct inner wall coating |

High temperature inner lining coating, hot air duct inner wall coating |