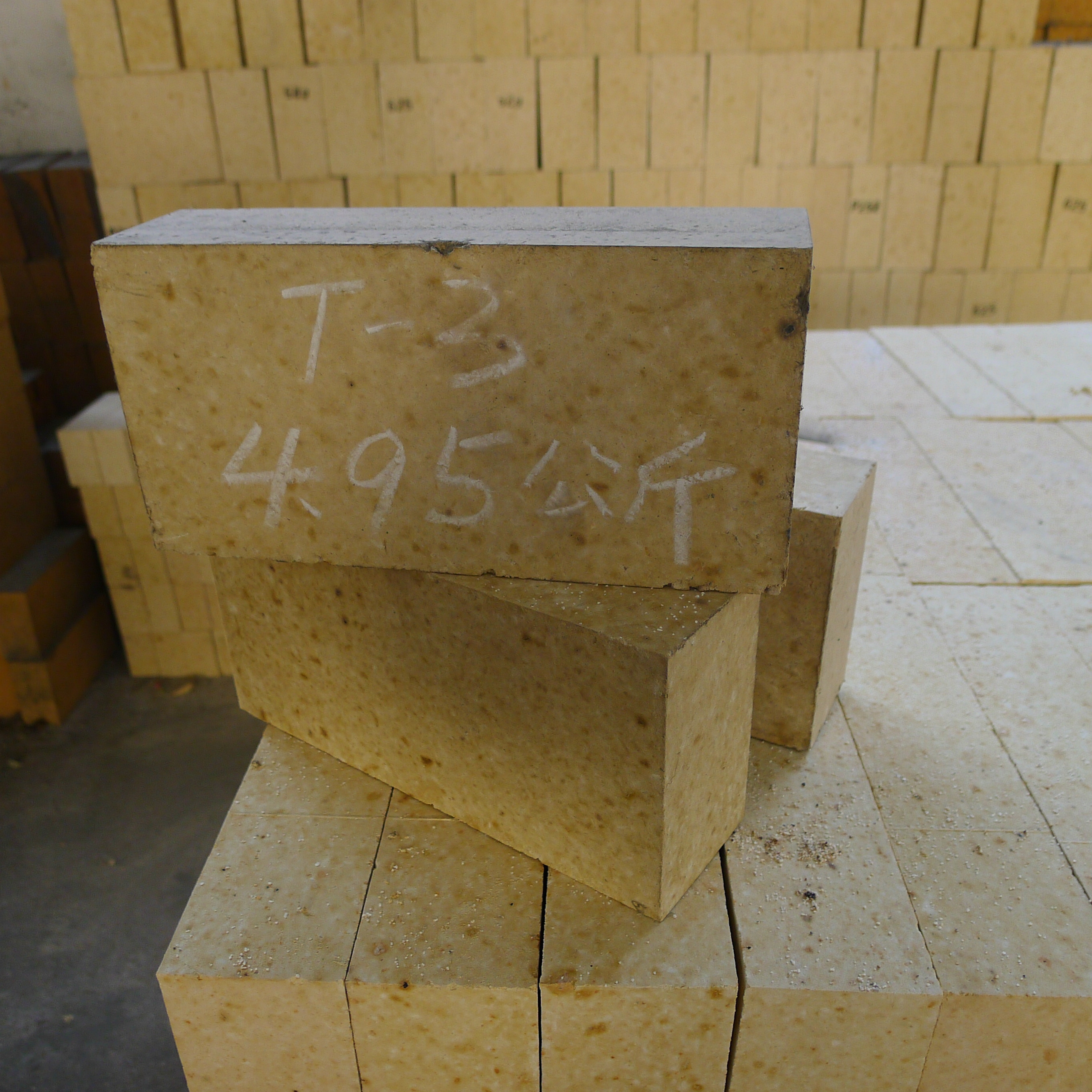

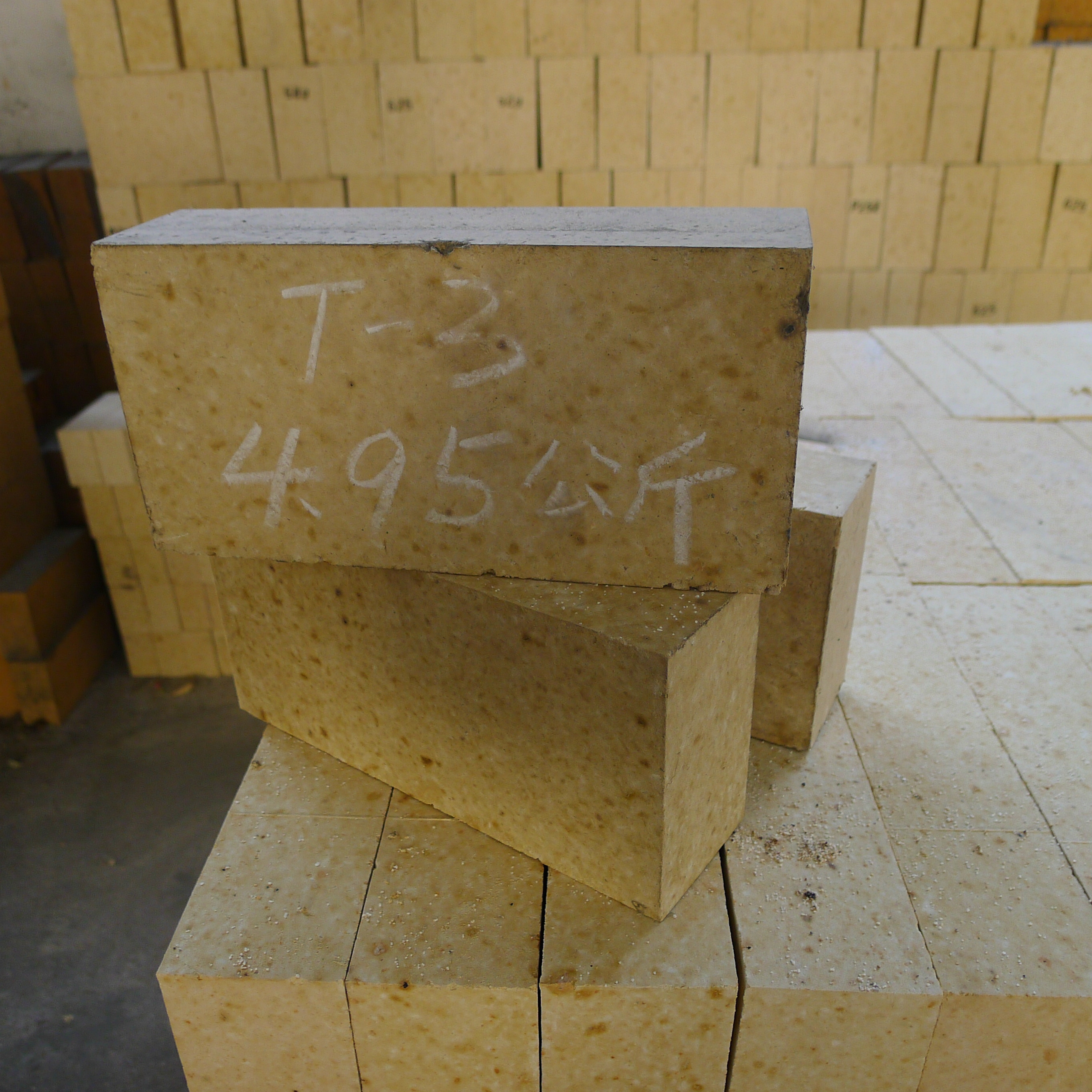

High Alumina Brick

High alumina bricks are the general names of alumina silicate refractory bricks, containing at least 48% Al2O3. The primary raw material used to make high alumina bricks is bauxite. To improve the high temperature performance of high alumina bricks, other minerals such as corundum, synthesized mullite, sillimate and so on are added into the raw material. High alumina bricks feature in high mechanical strength and high refractoriness. The thermal shock resistance of high alumina brick is not so good as that of fireclay brick, therefore, synthesized cordierite can be added into raw material to improve high alumina brick thermal shock resistance.

High alumina are divided into different types according to physiochemical properties: phosphate bonded high alumina brick, low creep high alumina brick, stripping resistant high alumina brick and so on.

Phosphate Bonded High Alumina Brick

Phosphate bonded high alumina bricks adopts phosphate solution or aluminum phosphate solution as binder. Phosphate bonded high alumina bricks are chemically bonded refractory bricks, they don’t need high temperature sintering, only heat treated at 400~600 °C It belongs to unburned firebricks. some thermal expansion materials such as kyanite, silimanite and silica can be added into phosphate bonded high alumina bricks raw material to compensate high temperature shrinkage during using.

Phosphate Bonded High Alumina Bricks Technical Index

| Item |

Phosphate bonded high alumina bricks |

Alumina phosphate bonded high alumina bricks |

| Al2O3 % > |

76 |

78 |

| Fe2O3 % < |

3.2 |

3.2 |

| CaO % < |

0.6 |

0.6 |

| Cold crushing strength Mpa > |

65 |

70 |

| Bulk density g/cm3 |

2.65 |

2.70 |

| Refractoriness under load ℃ > |

1350 |

1300 |

| Refractoriness ℃ > |

1790 |

1790 |

Phosphate Bonded High Alumina Bricks Application

Compared with ceramic bonded high-alumina bricks, phosphate bonded high alumina bricks have better spalling resistance and better thermals shock resistance. Phosphate binding high alumina bricks are mainly used in rotary cement kiln pre-combustion zone, decomposition zone, kiln door shield, and cooling machine inner linings, where bricks are easy to fall off.

Wear resistant high alumina bricks

Wear resistant high alumina bricks adopts bauxite clinker(less than 5mm) as aggregate, aluminum phosphate as binder, it is more compactly pressed, with high mechanical strength, wear resistance, but lower thermal shock resistance. wear resistant high alumina bricks are mainly used at transition zone and sintering zone of middle size and small size dry rotary cement kilns. Wear resistant high alumina bricks are also used in electric furnace top, ladles and so on.

Low Creep High Alumina Brick

Low creep high alumina brick is produced on the basis of three stones (kyanite, andalusite and silimanite) theory, its chemical composition is close to theoretical composition of mullite. Low creep high alumina bricks feature in low creep rate, good thermal shock resistance and high refractoriness.

Low Creep High Alumina Bricks Technical Index

| Item |

DRL-135 |

DRL-145 |

DRL-150 |

DRL-165 |

DRL-155 |

DRL-48 |

| Al2O3, % ≥ |

70 |

75 |

80 |

65 |

55 |

48 |

| Refractoriness ℃ ≥ |

1790 |

1790 |

1790 |

1790 |

1770 |

1750 |

| Apparent porosity % ≤ |

20 |

20 |

19 |

24 |

24 |

24 |

| Cold crushing strength MPa ≥ |

65 |

70 |

80 |

49 |

44.1 |

39.2 |

| Reheating linear change rage % ≥ |

±0.1 |

±0.1 |

±0.1 |

+0.1~-0.4 |

+0.1~-0.4 |

+0.1~-0.4 |

| 1450℃*2h |

1500℃*x2h |

1450℃*2h |

| refractoriness under load (0.2Mpa) ℃ ≥ |

1500 |

1550 |

1650 |

1500 |

1470 |

1420 |

| Creep rate % ≤ |

0.6

1350℃×50h |

0.6 |

0.7 |

- |

- |

- |

| 1450℃×50h |

1500℃×50h |

- |

- |

- |

Low creep high aluminum bricks are widely used in high temperature industrial kilns and furnaces. For example, hot blast furnaces and blast furnace inner lining, glass melting bath where doesn’t contact with glass, etc. Low creep high alumina bricks are also used as checker bricks.

Stripping Resistant High Alumina Brick

Stripping resistant high alumina brick is specially developed refractory products for alumina production kiln sintering zone. The raw materials of anti stripping high alumina bricks are special grade high alumina bauxite clinker and ZrO2 containing synthesized material.

Stripping Resistant High Alumina Bricks Physiochemical Index

| Item |

KBLZ-75 |

KBLZ-70 |

| Al2O3 % ≥ |

75 |

70 |

| Apparent porosity % ≤ |

23 |

25 |

| Refractoriness ℃ ≥ |

1790 |

1790 |

| Bulk density g/m3 ≥ |

2.6 |

2.55 |

| Cold crushing strength Mpa ≥ |

60 |

45 |

| 0.2Mpa Refractoriness under load beginning temperature ℃ ≥ |

1450 |

1470 |

| Thermal shock resistance/ times(1100℃, water cooling) ≥ |

10 |

20 |

| Thermal conductivity (1000℃) ≤ |

1.4 |

1.4 |

Stripping resistant high alumina bricks are mianly used in new type dry cement kilns, shaft Bohr kilns and wet cement kilns. The application parts include: kiln hood, ascending flue, cooling zone, decomposition zone, safety zone, transition zone, cooling machine backwall and sidewall, crossbeam arch, etc. Anti-stripping high alumina bricks almost successfully applied in all parts of cement kilns.