Zircon corundum bricks are made from five kinds of raw material: alumina, zircon sand, zirconia enriched sand, pure alkali, borax.

1. Alumina usually refers to industrial alumina, water content should be less than 0.3%, calcining loss should be less than 15%, about 0.62t of alumina is needed for the production of 1t AZS-33 fused bricks.

2. Zircon sand will cause the dyeing of AZS products, and there will have coarse crystal sand hole, which can lead to crack during cooling, and it can also affect the oxidization craft of AZS bricks, so its content should be less than 2%.

3. Zircon enriched sand. The SiO2 in AZS all comes from zircon, if the content is not enough, the rest can be provided by zircon enriched sand.

4. Pure alkali usually refers to sodium oxide, as the fluxing agent of AZS, second grade sodium oxide is often used, a ton of ASZ-33 usually needs 20kg pure alkali.

5. Borax is also the fluxing agent of AZS bricks, a tong of AZS-33 fused bricks needs about 20kg of borax sand.

Zircon corundum bricks adopts high quality zriconia(ZrO2) and corundum clinker as raw material, the production processes include: tempering, molding, drying, and high temperature sintering in shuttle kiln. This kind of zircon based bricks have dense crystalline structure, high bulk density, high mechanical strength at room temperature and high temperature, good thermal shock stability, little reheating shrinkage, small high temperature creep rate, and high chemical stability and high alkaline media corrosion resistance.

Zircon corundum products are widely used in industrial kilns of metallurgy, building material, petrol, chemical, ceramics, glass, enamel, carbon black, nonferrous metals, refractory materials, etc.

Zircon corundum bricks price is decided by physiochemical indexes,production craft and drawing dimension.

Zircon Corundum Bricks Specification

| Item |

Fused Cast Alumina |

Fused Cast Alumina |

Fused Cast Alumina |

| |

a-b Alumina RS-M |

a-Alumina RS-A |

b-Alumina RS-H |

| Chemical Composition |

Al2O3 |

94 |

98.5 |

93 |

| |

SiO2 |

1 |

0.4 |

- |

| |

NaO2 |

4 |

0.9 |

6.5 |

| |

Other oxides |

1 |

0.2 |

0.5 |

Crystallograghic

Analysis % |

a-Al2O3 |

44 |

90 |

- |

| |

Vitreous |

55 |

4 |

99 |

| |

Vitreous Phase |

1 |

6 |

1 |

There are 3 factors should be noticed during purchasing zircon corundum bricks

1. Indexes

As known for all, different materials of refractory bricks have different performances. Corundum bricks also have different performances based on different raw materials, for example, brown corundum, white corundum, black corundum and so on. Therefore, during purchasing corundum bricks, the firebrick production factory should provide corundum bricks quality inspection report, to make sure the indexes of corundum bricks can meet customer’s requirement.

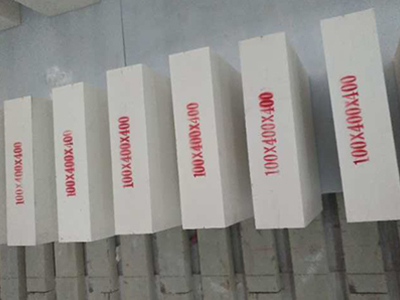

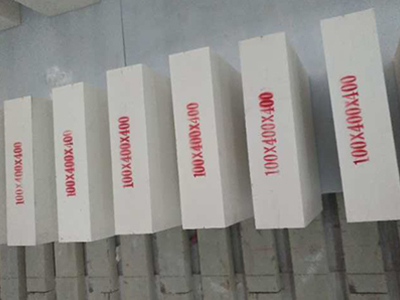

2. Dimension specifications

Corundum bricks are divided into standard shape, special shaped bricks, sometimes, some bricks should be designed and produced by refractory bricks producers, so when customers are purchasing corundum bricks, they should make sure the sizes of the corundum bricks is accordant with the draft. After the production of the bricks, they should be further processed and marked. When the bricks are ready to deliver, they should also be marked, so it is convenient for the masonry.

3. Zircon corundum manufacturer

Corundum bricks belong to refractory bricks, as the purchaser of corundum bricks, only if the provide physiochemical indexes, dimension specifications and other information of general application corundum bricks, the producers can carry out the production. But for special corundum bricks, such as fused corundum bricks, chrome corundum bricks and so on, which need special batching formula and processing craft, not every factory has production ability, so when you are choosing refractory bricks producer, you should learn more information about the factory.

Zhengzhou Rongsheng Kiln Refractory Produce Zircon corundum brick,

contact us

|

|