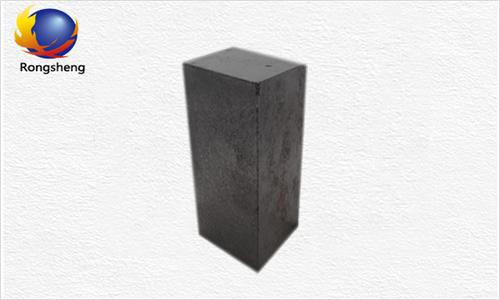

Carbon Brick Introduction

Carbon brick has good thermal stability, small thermal expansion coefficient and high temperature resistance. Carbon brick is not only widely used in metallurgical industry, but also used in aluminum electrolytic tank to resist various acid, alkali, salt and organic solvent erosion, but in oxidizing atmosphere and easy to oxidize.

Carbon Brick Feature

1.Carbon brick have high refractoriness.

2..Carbon fire brick have high wear resistance.

3.Carbon refractory brick have good slag resistance.

4.Carbon fire brick have high wear resistance.

5. Refractory carbon brick have large compressive strength.

Carbon Brick Specification

| Item |

unit |

Index |

| Ash |

% |

8 |

| Cold Crushing Strength |

Mpa |

38 |

| Apparent Porosity |

% |

20 |

| Bulk Density |

g/cm3 |

1.56 |

Carbon Brick Application

1.Carbon fire bricks are not only widely used in the metallurgical industry, but also in aluminum electrolysis cells.

Carbon Brick is suitable for Ore furnace

Carbon Brick Advantage

1.Refractory Carbon Brick to Achieve Microporous or Ultramicroporous

molten iron mainly penetrates into the interior of the carbon brick along the large-aperture holes and cracks of the refractory carbon brick.

Therefore, carbon refractory brick realizes micropores or ultramicropores, reduces pores with a pore diameter larger than 1 μm, which prevents the molten iron from infiltrating into the carbon fire brick.Thereby slowing the erosion of carbon bricks by molten iron.

2.Carbon Brick to Achieve Stomatal Closure

The main channel for the penetration of molten iron into the interior of carbon refractory bricks is the pores of carbon bricks.

3.Improve Thermal Conductivity of Refractory Carbon Bricks

Increasing the thermal conductivity of carbon bricks is an effective measure to improve the cooling effect of carbon bricks, reduce the temperature of carbon bricks, and slow down the erosion rate of carbon bricks.

4.Improve Resistance of Working Layer Carbon Bricks to Anti Iron Water Erosion

Carbon Brick Manufacturer In RS Refractory Factory

ZHENGZHOU RONGSHENG KILN REFRACTORY CO., LTD specializing in the production of refractory materials for nearly 20 years, now has formed a comprehensive enterprise for the production of refractory materials for the metallurgy, building materials, power, and chemical industries.

Rongsheng refractory company was founded in the 1990s, main products are alumina refractory products and unshaped refractory materials.

Alumina refractory products mainly include high alumina bricks, mullite corundum bricks, silica bricks, corundum bricks.

Refractory products are widely used in black and non-ferrous metal smelting, chemical industry.

Rongsheng refractory company with professional design team and technical team. Rongsheng group can design the refractory configuration plan and construction plan according to your furnace condition and construction conditions, and provide on-site guidance construction.